It has many varieties, usually produced using PU raw materials, with stable quality, high pressure resistance, weather resistance, wear resistance, resistance to twists and turns, smooth and flexible pipe body, bright color, high elasticity, resistance to winding, and small bending radius.

performance comparison of plastics for blow molding pneumatic pipe. The Pneumatic tube formed by blow molding is in a thermo elastic state, and its density is smaller than that after cooling and setting, resulting in shrinkage. For Pneumatic tube with less strict size, the molding shrinkage has little effect. For Pneumatic tube of specified size, such as some hoses used for precision machines, large shrinkage has a considerable impact. The larger the volume of blow molding, the more significant the impact. The advantages of extruding blown plastic forming Pneumatic tube are: less investment in production equipment, simple equipment structure, easy mold manufacturing, high molding of pneumatic tube during production, uniform temperature control, and various specifications of Pneumatic tube can be formed. The disadvantage is that the wall thickness uniformity of Pneumatic tube is poor. The advantages of injection blown Pneumatic tube are that the molded plastic Pneumatic tube has good product quality, accurate overall dimensions, no seam, uniform wall thickness, can be produced by multi mold molding, high degree of automation, and is suitable for mass and efficient production of small specifications. The disadvantage is that the investment in equipment and forming molds is relatively large, and technical workers are required for operation and production.

Product Name: 80A Ester-based Series

Item No.:XG1180

Features

Polyester type,

80A low melting point type,

very suitable for high-frequency heat sealing processing,

solvent resistance,

strong weather resistance,

no segregation,

and resistance to yellowing

Grade

Class 4.0, test method:300W340 UV irradiation for 24 hours, 50 ° C

colour

Transparent, natural matte , matte, various surface textures (fine fabric, fine matte, etc.) Color matching (with minimum order quantity requirements for colors)

Specifications

Thickness: 0.05mm-0.5mm(Accept Customization)

Width: 10-1500mm(Accept Customization)

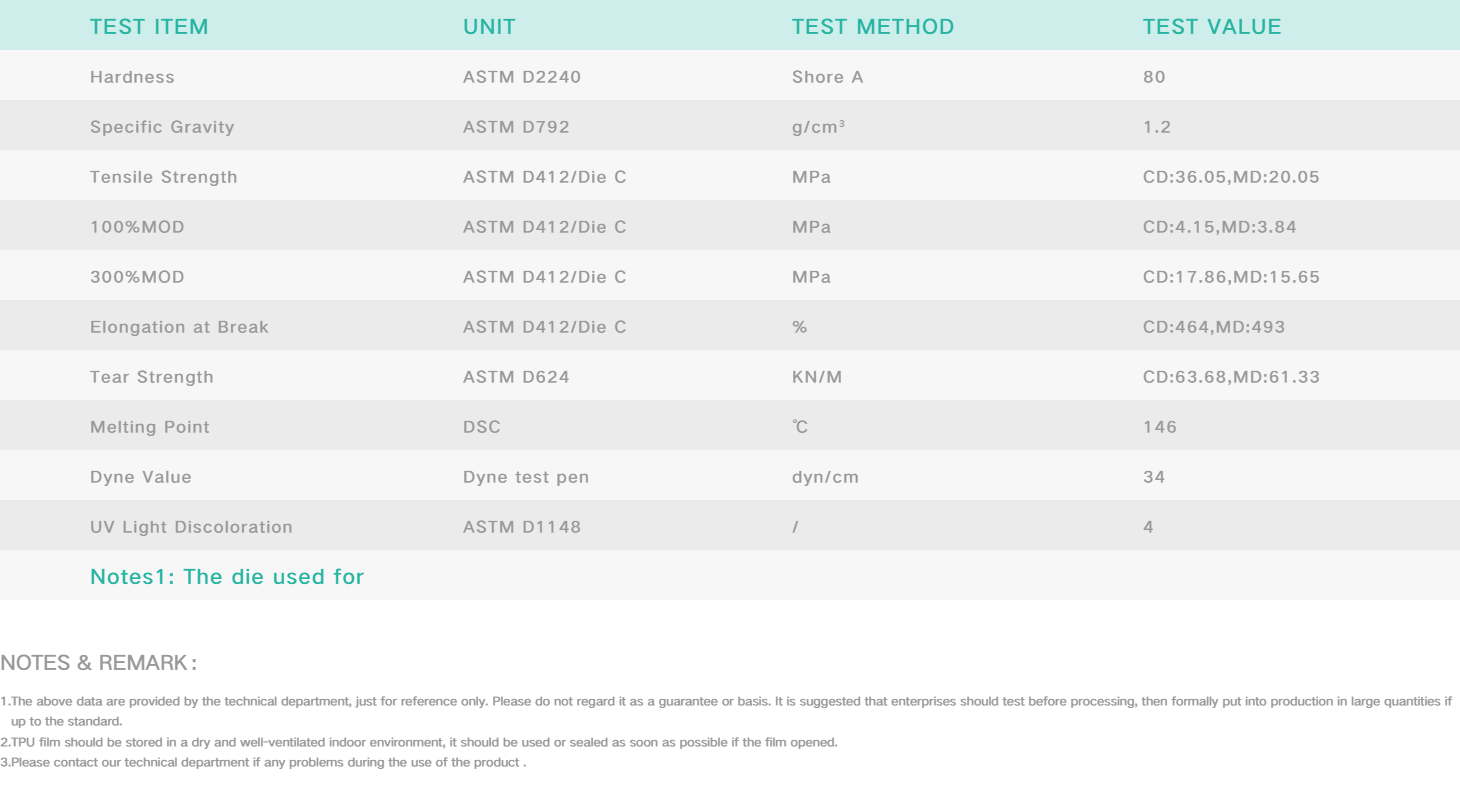

Basic physical properties

Q: Are you a manufacturer?

A: Yes, we are a specialized manufacturer of TPU film based in Shanghai. We have also established branches in Shenzhen and Los Angeles to better serve our global clients. We are committed to providing high-quality material solutions worldwide.

Q: How many production machines do you have?

A: Our factory is equipped with over 10 advanced production machines, covering all stages of manufacturing from raw material processing to final product. Our equipment and technical capabilities allow us to meet the needs of orders of various scales, ensuring efficient production and stable supply.

Q: How far is your factory from the airport?

A: Our factory is conveniently located approximately 30 minutes by car from Hongqiao International Airport and about 1 hour from Pudong International Airport. This advantageous location facilitates customer visits and logistical transport.

Q: What certifications do you have?

A: We are committed to stringent quality and safety controls and have obtained multiple international certifications, including ISO 9001:2015, OEKO-TEX, SGS, REACH, ROHS, IATF16949, FDA, and EU 2011 certifications.

Q: What is your Minimum Order Quantity (MOQ)?

A: Our typical MOQ ranges from 500 to 1000KG, depending on the product type and specifications. For regular products, we also maintain some inventory to flexibly meet urgent customer needs.

Q: What are your pricing terms?

A: Since customer requirements may vary, our pricing is tailored based on specific order volumes, specifications, and other factors. Please send your detailed requirements to our sales team, and we will provide you with a competitive quote as soon as possible.

Q: What are your payment terms?

A: We offer flexible payment terms, including Telegraphic Transfer (T/T), Letter of Credit (L/C), and PayPal, to provide a more convenient transaction experience for our customers.

Q: What is your delivery time?

A: Our standard delivery time is 10 to 20 days after receiving the deposit. The exact time frame may vary depending on the complexity of the order and the production schedule. We are committed to on-time delivery to ensure that your project timeline remains unaffected.

Q: Can you provide samples?

A: Certainly! We are pleased to offer potential customers up to 1KG of free samples for testing and evaluation. The freight can be collected on delivery or charged to your courier account.

XinGen(Shenzhen)Co., Ltd. belongs to Shanghai Xin Gen, established in 2009. Headquarters, R&D, and factory are in Shanghai, over 6,000 sqm. Sales branches in Shenzhen and LA in 2023. Specializes in high-end TPU products, sold globally, covering multiple fields.

Copyright © 2024 XinGen(Shenzhen)Co., Ltd. All Rights Reserved.